- Bending Technical Guide

- Bending Type & Die V Selection

Bending Type & Die V Selection

Bend Technique

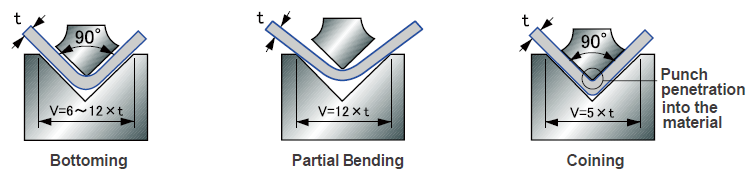

| Air Bend | Bottoming | The work surface and die surface contact after bend. Bending accuracy is gained with relatively smaller tonnage. This is the most popular bending technique. |

|---|---|---|

| Partial Bending | Work surface & die surface do not contact after bend. The work is bent without reaching to die bottom. |

|

| Coining | Punch edge penetrates into the work and this prevents the work from spring-back. Very good accuracy is gained but 5 - 8 times more tonnage than bottoming is required. |

|

Die V-Width Selection

V-opening is determined by the work thickness:t as well as bending tonnage, product's inner radius

(iR) and minimum flange length.

Although V-width selection by thickness:t is shown in the table below, two vital factors must be

checked whether iR is acceptable or not and min. flange length by V value is acceptable or not

because once V-width is selected iR becomes approx. iR=V/6 and min.flange length is fixed by

V-value.

| V Width | ||||

|---|---|---|---|---|

| Thickness t (mm) | 0.5 - 2.6 | 3.0 - 8 | 9 - 10 | 12 more |

| Bottoming | 6×t | 8×t | 10×t | 12×t |

| Partial Bending | 12 - 15×t | |||

| Coining | 5 x t | |||