- TOP

- Punching Solutions

- V-CUT TOOL TOP

- V-CUT TOOL: Caution

V-CUT TOOL

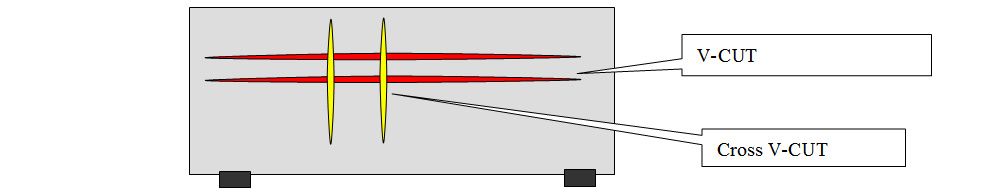

① Cross V-CUT can be performed, but V-CUT insert will be chipped easily. Please check cutting-chips, tool and V-CUT insert regularly.

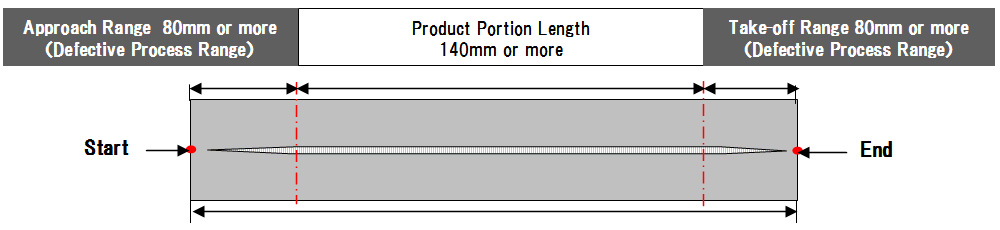

② V-CUT Process Min. Length for Product Portion: 140mm (Approach Range / Take-off Range are not included.)

③ Required Material Length: Approach Range (80mm or more) + Product Portion Length (140mm or more) + Take-off Range (80mm or more).

Material Length=Approach Range (80mm or more)+Product Length (140mm or more)+Take-off Range(80mm or more)

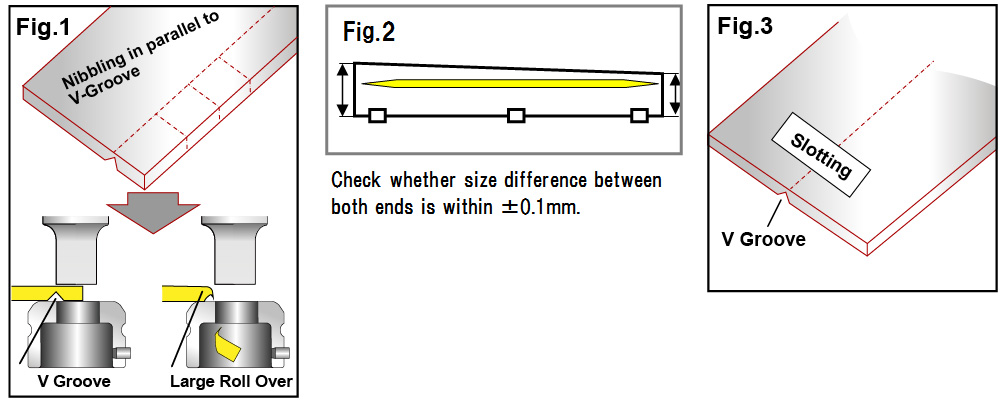

④ The roll over appears on material surface if nibbling was performed on V groove. (Fig.1)

⑤ Aluminum is not acceptable because it causes the welding of chips and the clogging of chips.

⑥ Do not perform over long time, continuous night operation and PDC auto tool changer operations.

⑦ If V-CUT is performed on sketch blank which has determined size in width direction, it will influence V groove straightness.

Please confirm cutting dimensional accuracy of material (within ±0.1 mm).(Fig.2)

⑧ If scrap conveyor belt is resin-type, the heat of discharged chips accelerates deterioration of the belt.

⑨ If V-CUT processing and slotting processing are crossed, the tooling will break or generate defectives by clogged punching chips.(Fig.3)