- TOP

- Punching Solutions

- V-CUT TOOL TOP

- V-CUT TOOL:Specification1

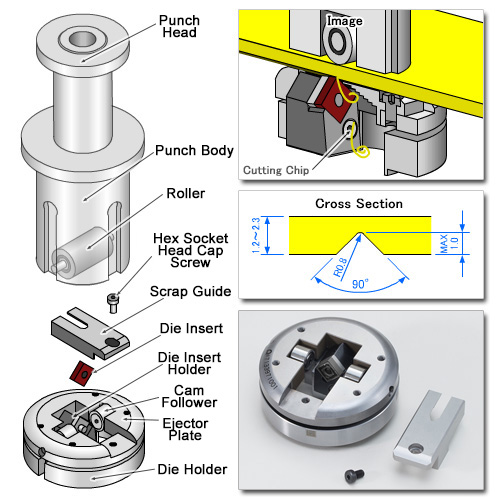

V-CUT TOOL

Specification1

| Tool Type | NCT Long Tool Cst:2" | |

|---|---|---|

| Component | V-CUT TOOL + Cutting Insert (1 piece) | |

| Material Thickness | 1.2-2.3mm | |

| Material | Mild Steel/Stainless (Aluminum is not available) | |

| Material Size | X size Min.914mm / X size≧Y size ×2 | |

| V-CUT Side | Undersurface | |

| V-CUT Style | Straight only (0 degree, 90 degree) This is applied for AI station as well |

|

| V-CUT Angle / R | 90 degree R0.8mm | |

| V-CUT Depth per path | Min0.03mm Max0.3mm | |

| Max V-CUT Depth | 1.0mm | |

| Insert | SUMITOMO ELECTRIC CUTTING INSERT SNMG12408N-EM-AC6040M ※1 | |

|---|---|---|

| Insert Life※2 (Recommended Value) |

SUS304 | 1,000 hits / Insert 1 edge 8,000 hits / Insert 1 piece (8 edges) ※The count is 2 hits per pass. [Process Condition] Thickness: 1.5mm / V groove depth: 1mm (5 pass) / V-CUT length: 2m ●Process length: 200m / Insert 1 edge 1,600m / Insert 1 piece (8 edges) |

| SUS430 | 500 hits / Insert 1 edge 4,000 hits / Insert 1 piece (8 edges) |

|

| Mild Steel |

2,000 hits / Insert 1 edge 16,000 hits / Insert 1 piece (8 edges) |

|

※1 Cutting insert type may change for improving process grade and durability.

※2 Continuous Operation Limit The insert may break and cause defects or clogging of chips in die if it is used over its service life.

| Max. Feed Speed | X-axis | EM(Z)-NT / EM-M2 / LSE : F100,000 100mm/min |

|---|---|---|

| V-CUT Depth Accuracy | Y-axis | EM(Z)-NT / EM-M2 : F80,000 80mm/min LSE : F60,000 60mm/min LC-C1NT / LC-C1AJ / AE : F55,000 55mm/min |

| V-CUT Straightness | Within ± 0.1mm ※Equal to machine accuracy (But , in some cases, finishing work is required.) |

|

| Dead Zone | 110mm or less (Lower end movable range) | |