- Bending Technical Guide

- How to Use and Select Tools (1) R-Bend

How to Use and Select Tools (1) R-Bend

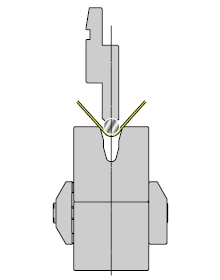

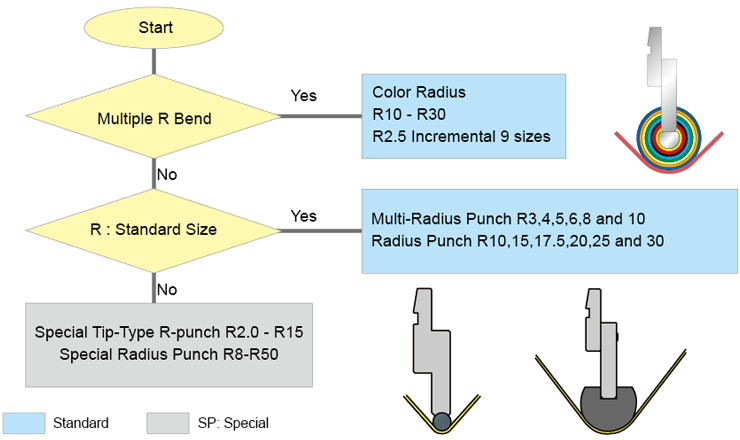

R-Bend by Standard Tools

| Multi-Radius Punch R3 , R4 , R5 , R6 , R8 , R10 |

Color Radius Punch R10 - R30 R2.5 incremental |

Radius Punch R10 , R15 , R17.5 , R20 , R25 , R30 |

|---|---|---|

|

|

|

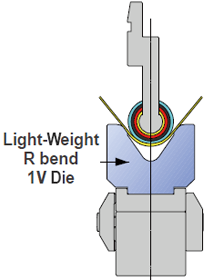

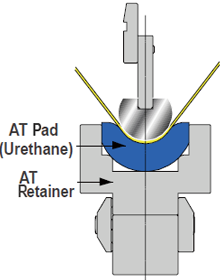

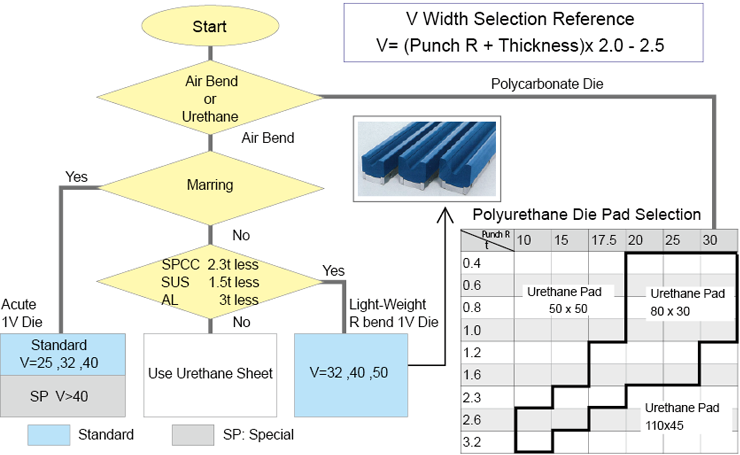

| Acute 1V Die | Light-weight R bend 1V Die Acute 1V Die |

AT Retainer (Urethane) Acute 1V Die Light-Weight R Bend 1V die |

Features

- 1 process makes easy R bend comparing step-R-Bending

* Shorter work time

* Stable accuracy

* Smoother R surface - Several R value can be adapted

- Cheaper and shorter lead time

Caution for R-Bending -1

Multi-Breakage

Multi-Breakage is typical phenomenon during bending process where the work separates from R-punch surface and the work breaks.1 the ratio of thickness t and product inner iR (iR/t) too big 2 the work’s tensile strength is low or lower ductility * When the ratio iR/t is more than 30, Multi-breakage occurs.

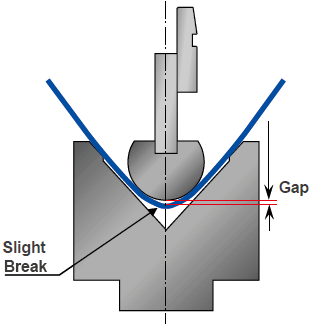

Caution for R-Bending -2

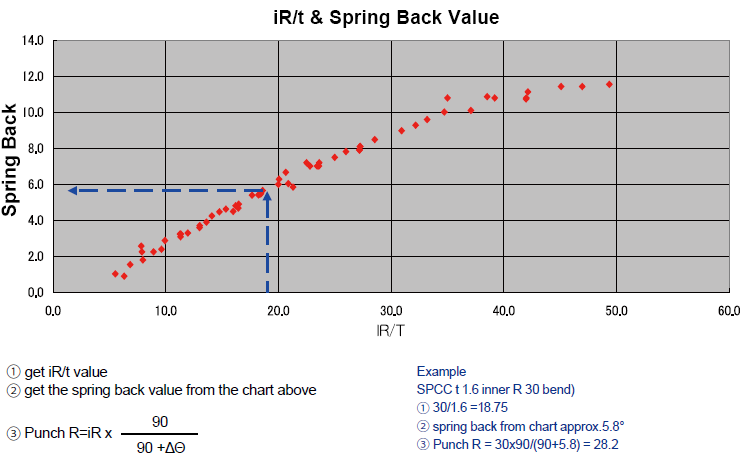

Spring back : Bend angle is larger when the load is off.

1 This spring back value of R-Bend is larger than the value of V-bend.

2 Generally, iR is larger than punch R.

Factor to the spring back

- Thickness and iR( inner radius ) iR/t

- strength of the Material

- tool type ( bending method & structure )

|

Material Type(%) | Tensile Strength N/mm2 | Elongation |

|---|---|---|---|

| SS400 | 410 - 520 | 17 or more | |

| SPCC | 280 or more | 38 or more | |

| SPHC | 280 or more | 29 or more | |

| A5052P | 180 or more | 19 or more | |

| A1100P | 75 or more | 30 or more | |

| SUS304 | 530 or more | 40 or more | |

| SUS430 | 460 or more | 22 or more |

How to decide punch tip-radius from product inner radius (iR)

Standard Punch Selection for R Bend

iR(inner radius) chart of SPCC air-bend by various thickness t and various punch R

* Die is selected by punch R

Example: SPCC t=1.0mm bent by R15 punch Chart tells inner radius approx. R16.2

| Thickness | R10 | R15 | R17.5 | R20 | R25 | R30 |

|---|---|---|---|---|---|---|

| 0.8 | 10.6 | 16.4 | 18.9 | 21.8 | 28 | 33.6 |

| 1 | 10.5 | 16.2 | 18.6 | 21.3 | 27.2 | 33.2 |

| 1.2 | 10.5 | 16 | 18.4 | 21.2 | 27 | 32.7 |

| 1.6 | 10.3 | 15.7 | 18.2 | 20.8 | 26.3 | 32 |

| 2.3 | 10.2 | 15.5 | 18 | 20.5 | 25.8 | 31.3 |

| 3.2 | 10.2 | 15.4 | 17.7 | 20.2 | 25.5 | 30.8 |

□Multi-Breakage Possible Area

iR( inner radius) chart of aluminum air-bend by various thickness t and various punch R

*Test made by A5052-0 and bent parallel to roll direction

*Die selection by punch R

Example : A5052-0 1.0mm thick using R20 punch inner radius becomes R24.4

* t=0.8 punch R30 multi-breakage occurred

![]()

| Thickness | Punch R | |||||

|---|---|---|---|---|---|---|

| R10 | R15 | R17.5 | R20 | R25 | R30 | |

| 0.6 | 12.1 | 19.5 | 23.0 | 27.6 | 38.0 | 45.8 |

| 18.9 | 27.0 | 28.3 | 34.2 | 46.8 | 47.4 | |

| 0.8 | 11.3 | 18.1 | 21.5 | 25.5 | 32.5 | 42.5 |

| 11.7 | 18.6 | 20.6 | 24.8 | 27.0 | 37.5 | |

| 1.0 | 11.1 | 17.4 | 20.8 | 24.4 | 30.7 | 37.4 |

| 9.9 | 14.4 | 17.0 | 19.8 | 20.5 | 22.2 | |

| 1.2 | 10.8 | 17.0 | 20.3 | 23.6 | 29.7 | 36.0 |

| 7.2 | 12.0 | 14.4 | 16.2 | 16.9 | 18.0 | |

| 1.5 | 10.6 | 16.5 | 19.6 | 22.8 | 28.7 | 34.8 |

| 5.4 | 9.0 | 10.8 | 12.6 | 13.3 | 14.4 | |

| 2.0 | 10.4 | 15.8 | 19.0 | 21.9 | 27.7 | 33.5 |

| 3.6 | 4.8 | 7.7 | 8.5 | 9.7 | 10.5 | |

| 2.5 | 10.2 | 15.6 | 18.7 | 21.5 | 27.4 | 33.0 |

| 1.8 | 3.6 | 6.2 | 6.8 | 8.6 | 9.0 | |

| 3.0 | 10.1 | 15.3 | 18.5 | 21.2 | 27.0 | 32.5 |

| 0.9 | 1.8 | 5.1 | 5.4 | 7.2 | 7.5 | |

□Multi-Breakage Possible Area