- TOP

- Bending Tools

- AFH Tooling

AFH Tooling

HG/EG/HDS/HD Recommendation

Return Bend Graph

* L:835mm M:510mm SS:200mm Ears:200mm (Right 100 Left 100) Sect.:370mm (10×2,15,20,25,40,50,100×2)

Sect. B:800mm (10,15,20,40,50,100,200,365) __:Order Item > Heavy Gauge Punch/Die

> Recommended Holder: FEAT AFH Die Holder

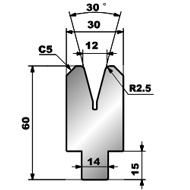

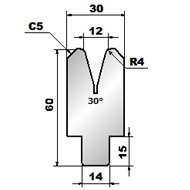

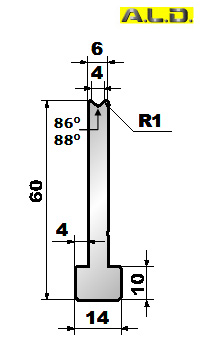

- Die 30°

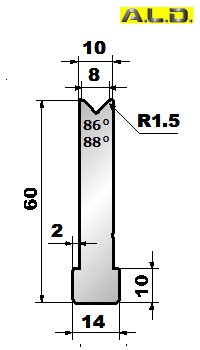

- Die 1

- Die 2

| Profile | Angle | V Width | W | CATNo. | Allowable Tonnage | Height | Weight (kg) |

Size |

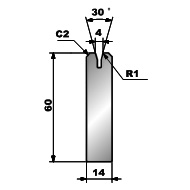

V=4  Hardness HRC55 |

30° | 4 | 14 | A84031 | 160kN/m | 60 | 5.3 | L |

| A84531 | 3.2 | M | ||||||

| A84732 | 1.3 | SS | ||||||

| A84831 | 2.3 | Sect. | ||||||

| S84631 | 5.0 | Sect. B | ||||||

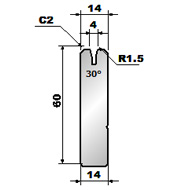

V=4 Type-R Hardness HRC55 |

R84031 | 5.3 | L | |||||

| R84531 | 3.2 | M | ||||||

| R84732 | 1.3 | SS | ||||||

| R84831 | 2.3 | Sect. | ||||||

| R8S631 | 5.0 | Sect. B | ||||||

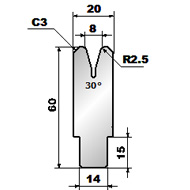

V=6 Hardness HRC55 |

30° | 6 | 17 | A70031 | 180kN/m | 60 | 6.1 | L |

| A70531 | 3.7 | M | ||||||

| A70732 | 1.5 | SS | ||||||

| A70831 | 2.7 | Sect. | ||||||

| S70631 | 5.8 | Sect. B | ||||||

V=6 Type-R Hardness HRC55 |

R70031 | 6.1 | L | |||||

| R70531 | 3.7 | M | ||||||

| R70732 | 1.5 | SS | ||||||

| R70831 | 2.7 | Sect. | ||||||

| R7063S | 5.8 | Sect. B | ||||||

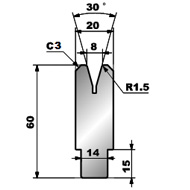

V=8 Hardness HRC55 |

30° | 8 | 20 | A71031 | 200kN/m | 60 | 6.8 | L |

| A71531 | 4.1 | M | ||||||

| A71732 | 1.6 | SS | ||||||

| A71831 | 3.0 | Sect. | ||||||

| S71631 | 6.4 | Sect. B | ||||||

V=8 Type-R Hardness HRC55 |

R71031 | 6.8 | L | |||||

| R71531 | 4.1 | M | ||||||

| R71732 | 1.6 | SS | ||||||

| R71831 | 3.0 | Sect. | ||||||

| RS1631 | 6.4 | Sect. B | ||||||

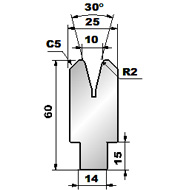

V=10 Hardness HRC55 |

30° | 10 | 25 | A72031 | 260kN/m | 60 | 8.2 | L |

| A72531 | 5.0 | M | ||||||

| A72732 | 1.9 | SS | ||||||

| A72831 | 3.6 | Sect. | ||||||

| S72631 | 7.7 | Sect. B | ||||||

V=10 Type-R Hardness HRC55 |

R72031 | 8.0 | L | |||||

| R72531 | 4.9 | M | ||||||

| R72732 | 1.9 | SS | ||||||

| R72831 | 3.6 | Sect. | ||||||

| RS2631 | 7.7 | Sect. B | ||||||

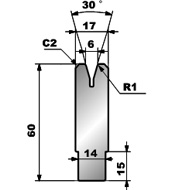

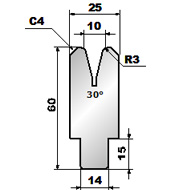

V=12 Hardness HRC55 |

30° | 12 | 30 | A74031 | 300kN/m | 60 | 9.1 | L |

| A74531 | 5.6 | M | ||||||

| A74732 | 2.2 | SS | ||||||

| A74831 | 4.0 | Sect. | ||||||

| S74631 | 8.8 | Sect. B | ||||||

V=12 Type-R Hardness HRC55 |

R74031 | 9.1 | L | |||||

| R74531 | 5.6 | M | ||||||

| R74732 | 2.2 | SS | ||||||

| R74831 | 4.0 | Sect. | ||||||

| R7S631 | 8.8 | Sect. B |

- AFH die has special relief in order to gain the perfect alignment and tooling origin. Please be sure to use the same angle for combination to obtain the origin position. If the origin position is determined by different angle combination, the first bend for the product may be more acute than expected angle.

- Hardness of AFHDies with A.L.D. are different from of AFHDies without A.L.D., so AFHDies with A.L.D. can not be used together with AFHDies without A.L.D..

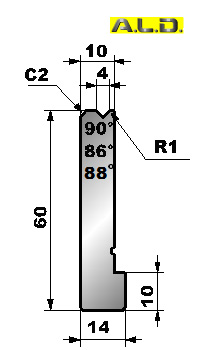

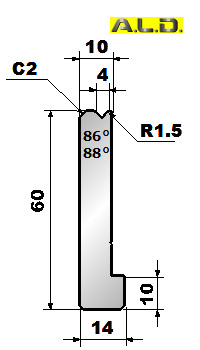

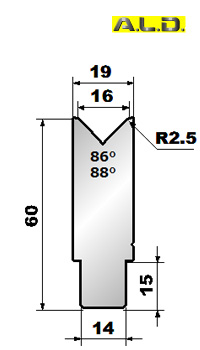

| Profile | Angle | V Width | W | CATNo. | Allowable Tonnage | Height | Weight (kg) |

Size |

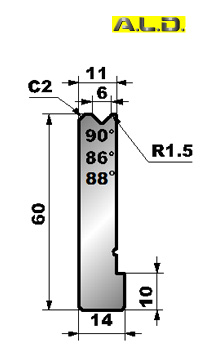

V=4 Hardness HRC55 |

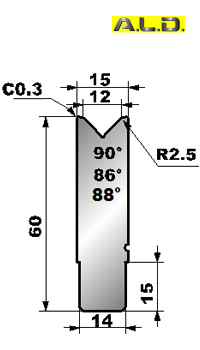

86° | 4 | 10 | A84061 | 750kN/m | 60 | 4.1 | L |

| A84561 | 2.5 | M | ||||||

| A84762 | 1.0 | SS | ||||||

| A84861 | 1.8 | Sect. | ||||||

| S84661 | 3.9 | Sect. B | ||||||

| 88° | A84081 | 4.1 | L | |||||

| A84581 | 2.5 | M | ||||||

| A84782 | 1.0 | SS | ||||||

| A84881 | 1.8 | Sect. | ||||||

| S84681 | 3.9 | Sect. B | ||||||

| 90° | A84091 | 4.1 | L | |||||

| A84591 | 2.5 | M | ||||||

| A84792 | 1.0 | SS | ||||||

| A84891 | 1.8 | Sect. | ||||||

V=4 Type-R Hardness HRC55 |

86° | R84061 | 4.1 | L | ||||

| R84561 | 2.5 | M | ||||||

| R84762 | 1.0 | SS | ||||||

| R84861 | 1.8 | Sect. | ||||||

| RS4661 | 3.9 | Sect. B | ||||||

| 88° | R84081 | 4.1 | L | |||||

| R84581 | 2.5 | M | ||||||

| R84782 | 1.0 | SS | ||||||

| R84881 | 1.8 | Sect. | ||||||

| R8S681 | 3.9 | Sect. B | ||||||

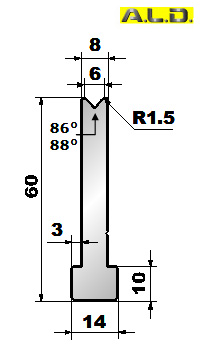

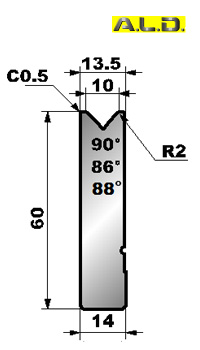

V=4 Type-T Hardness HRC55 |

86° | 6 | T84061 | 2.8 | L | |||

| T84561 | 1.7 | M | ||||||

| T84762 | 0.7 | SS | ||||||

| T84861 | 1.2 | Sect. | ||||||

| T8S661 | 2.7 | Sect. B | ||||||

| 88° | T84081 | 2.8 | L | |||||

| T84581 | 1.7 | M | ||||||

| T84782 | 0.7 | SS | ||||||

| T84881 | 1.2 | Sect. | ||||||

| TS4681 | 2.7 | Sect. B | ||||||

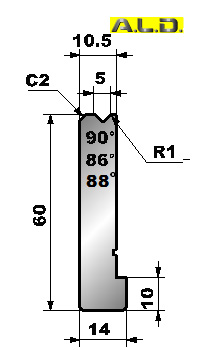

V=5 Hardness HRC55 |

86° | 5 | 10.5 | A85061 | 750kN/m | 60 | 4.3 | L |

| A85561 | 2.6 | M | ||||||

| A85762 | 1.0 | SS | ||||||

| A85861 | 1.9 | Sect. | ||||||

| S85661 | 4.1 | Sect. B | ||||||

| 88° | A85081 | 4.3 | L | |||||

| A85581 | 2.6 | M | ||||||

| A85782 | 1.0 | SS | ||||||

| A85881 | 1.9 | Sect. | ||||||

| S85881 | 4.1 | Sect. B | ||||||

| 90° | A85091 | 4.3 | L | |||||

| A85591 | 2.6 | M | ||||||

| A85792 | 1.0 | SS | ||||||

| A85891 | 1.9 | Sect. | ||||||

V=5 Type-R Hardness HRC55 |

86° | R85061 | 4.3 | L | ||||

| R85561 | 2.6 | M | ||||||

| R85762 | 1.0 | SS | ||||||

| R85861 | 1.9 | Sect. | ||||||

| RS5661 | 4.1 | Sect. B | ||||||

| 88° | R85081 | 4.3 | L | |||||

| R85581 | 2.6 | M | ||||||

| R85782 | 1.0 | SS | ||||||

| R85881 | 1.9 | Sect. | ||||||

| RS5681 | 4.1 | Sect. B | ||||||

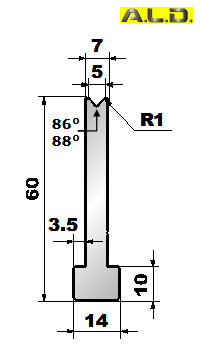

V=5 Type-T Hardness HRC55 |

86° | 7 | T85061 | 3.1 | L | |||

| T85561 | 1.9 | M | ||||||

| T85762 | 0.8 | SS | ||||||

| T85861 | 1.4 | Sect. | ||||||

| TS5661 | 3.0 | Sect. B | ||||||

| 88° | T85081 | 3.1 | L | |||||

| T85581 | 1.9 | M | ||||||

| T85782 | 0.8 | SS | ||||||

| T85881 | 1.4 | Sect. | ||||||

| TS5681 | 3.0 | Sect. B | ||||||

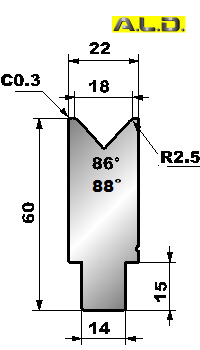

V=6 Hardness HRC55 |

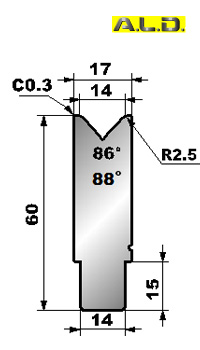

86° | 6 | 11 | A70061 | 800kN/m | 60 | 4.4 | L |

| A70561 | 2.7 | M | ||||||

| A70762 | 1.1 | SS | ||||||

| A70861 | 1.9 | Sect. | ||||||

| S70661 | 4.2 | Sect. B | ||||||

| 88° | A70081 | 4.4 | L | |||||

| A70581 | 2.7 | M | ||||||

| A70782 | 1.1 | SS | ||||||

| A70881 | 1.9 | Sect. | ||||||

| S70681 | 4.2 | Sect. B | ||||||

| 90° | A70091 | 4.4 | L | |||||

| A70591 | 2.7 | M | ||||||

| A70792 | 1.1 | SS | ||||||

| A70891 | 1.9 | Sect. | ||||||

V=6 Type-T Hardness HRC55 |

86° | 8 | T70061 | 3.4 | L | |||

| T70561 | 2.1 | M | ||||||

| T70762 | 0.8 | SS | ||||||

| T70861 | 1.5 | Sect. | ||||||

| TS0661 | 3.3 | Sect. B | ||||||

| 88° | T70081 | 3.4 | L | |||||

| T70581 | 2.1 | M | ||||||

| T70782 | 0.8 | SS | ||||||

| T70881 | 1.5 | Sect. | ||||||

| TS0681 | 3.3 | Sect. B | ||||||

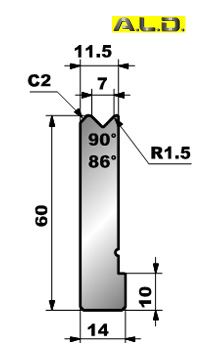

V=7 Hardness HRC55 |

86° | 7 | 11.5 | A86061 | 850kN/m | 60 | 4.6 | L |

| A86561 | 2.8 | M | ||||||

| A86762 | 1.1 | SS | ||||||

| A86861 | 2.0 | Sect. | ||||||

| 90° | A86091 | 4.6 | L | |||||

| A86591 | 2.8 | M | ||||||

| A86792 | 1.1 | SS | ||||||

| A86891 | 2.0 | Sect. | ||||||

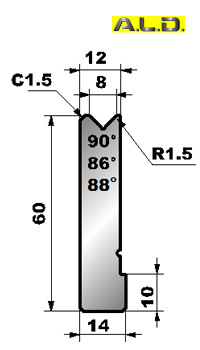

V=8 Hardness HRC55 |

86° | 8 | 12 | A71061 | 900kN/m | 60 | 4.7 | L |

| A71561 | 2.9 | M | ||||||

| A71762 | 1.1 | SS | ||||||

| A71861 | 2.1 | Sect. | ||||||

| S71661 | 4.6 | Sect. B | ||||||

| 88° | A71081 | 4.7 | L | |||||

| A71581 | 2.9 | M | ||||||

| A71782 | 1.1 | SS | ||||||

| A71881 | 2.1 | Sect. | ||||||

| S71681 | 4.6 | Sect. B | ||||||

| 90° | A71091 | 4.7 | L | |||||

| A71591 | 2.9 | M | ||||||

| A71792 | 1.1 | SS | ||||||

| A71891 | 2.1 | Sect. | ||||||

V=8 Type-T Hardness HRC55 |

86° | 10 | T71061 | 4.1 | L | |||

| T71561 | 2.5 | M | ||||||

| T71762 | 1.0 | SS | ||||||

| T71861 | 1.8 | Sect. | ||||||

| TS1661 | 3.9 | Sect. B | ||||||

| 88° | T71081 | 4.1 | L | |||||

| T71581 | 2.5 | M | ||||||

| T71782 | 1.0 | SS | ||||||

| T71881 | 1.8 | Sect. | ||||||

| TS1681 | 3.9 | Sect. B | ||||||

V=10 Hardness HRC55 |

86° | 10 | 13.5 | A72061 | 1000kN/m | 60 | 5.1 | L |

| A72561 | 3.1 | M | ||||||

| A72762 | 1.2 | SS | ||||||

| A72861 | 2.3 | Sect. | ||||||

| S72661 | 4.9 | Sect. B | ||||||

| 88° | A72081 | 5.1 | L | |||||

| A72581 | 3.1 | M | ||||||

| A72782 | 1.2 | SS | ||||||

| A72881 | 2.3 | Sect. | ||||||

| S72681 | 4.9 | Sect. B | ||||||

| 90° | A72091 | 5.1 | L | |||||

| A72591 | 3.1 | M | ||||||

| A72792 | 1.2 | SS | ||||||

| A72891 | 2.3 | Sect. | ||||||

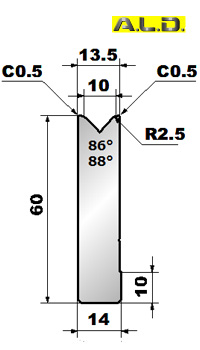

V=10 Type-R Hardness HRC55 |

86° | R72061 | 5.1 | L | ||||

| R72561 | 3.1 | M | ||||||

| R72762 | 1.2 | SS | ||||||

| R72861 | 2.3 | Sect. | ||||||

| R7S661 | 4.9 | Sect. B | ||||||

| 88° | R72081 | 5.1 | L | |||||

| R72581 | 3.1 | M | ||||||

| R72782 | 1.2 | SS | ||||||

| R72881 | 2.3 | Sect. | ||||||

| R7S681 | 4.9 | Sect. B | ||||||

V=10 Type-T Hardness HRC55 |

86° | 13 | T72061 | 4.9 | L | |||

| T72561 | 3.0 | M | ||||||

| T72762 | 1.2 | SS | ||||||

| T72861 | 2.2 | Sect. | ||||||

| T7S661 | 4.7 | Sect. B | ||||||

| 88° | T72081 | 4.9 | L | |||||

| T72581 | 3.0 | M | ||||||

| T72782 | 1.2 | SS | ||||||

| T72881 | 2.2 | Sect. | ||||||

| T7S681 | 4.7 | Sect. B |

- AFH die has special relief in order to gain the perfect alignment and tooling origin. Please be sure to use the same angle for combination to obtain the origin position. If the origin position is determined by different angle combination, the first bend for the product may be more acute than expected angle.

- Oxidized scale is peeled out from SPH( hot rolled steel ) when SPH material is bent, so clean the die groove regularly. AX Tool ( best for stainless and heavy gauge plate bending) is recommended for SPH material bending.

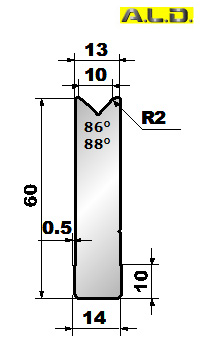

| Profile | Angle | V Width | W | CATNo. | Allowable Tonnage | Height | Weight (kg) |

Size |

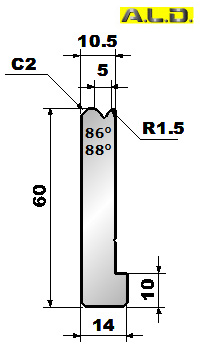

V=12 Hardness HRC55 |

86° | 12 | 15 | A74061 | 1000kN/m | 60 | 5.5 | L |

| A74561 | 3.4 | M | ||||||

| A74762 | 1.3 | SS | ||||||

| A74861 | 2.4 | Sect. | ||||||

| S74661 | 5.3 | Sect. B | ||||||

| 88° | A74081 | 5.5 | L | |||||

| A74581 | 3.4 | M | ||||||

| A74782 | 1.3 | SS | ||||||

| A74881 | 2.4 | Sect. | ||||||

| S74681 | 5.3 | Sect. B | ||||||

| 90° | A74091 | 5.5 | L | |||||

| A74591 | 3.4 | M | ||||||

| A74792 | 1.3 | SS | ||||||

| A74891 | 2.4 | Sect. | ||||||

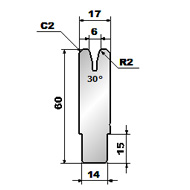

V=14 Hardness HRC55 |

86° | 14 | 17 | A76061 | 1000kN/m | 60 | 6.0 | L |

| A76561 | 3.7 | M | ||||||

| A76762 | 1.4 | SS | ||||||

| A76861 | 2.7 | Sect. | ||||||

| S76661 | 5.8 | Sect. B | ||||||

| 88° | A76081 | 6.0 | L | |||||

| A76581 | 3.7 | M | ||||||

| A76782 | 1.4 | SS | ||||||

| A76881 | 2.7 | Sect. | ||||||

| S76681 | 5.8 | Sect. B | ||||||

V=16 Hardness HRC55 |

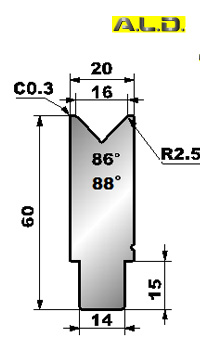

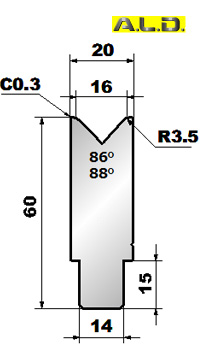

86° | 16 | 20 | A77061 | 1000kN/m | 60 | 6.8 | L |

| A77561 | 4.1 | M | ||||||

| A77762 | 1.6 | SS | ||||||

| A77861 | 3.0 | Sect. | ||||||

| S77661 | 6.4 | Sect. B | ||||||

| 88° | A77081 | 6.8 | L | |||||

| A77581 | 4.1 | M | ||||||

| A77782 | 1.6 | SS | ||||||

| A77881 | 3.0 | Sect. | ||||||

| S77681 | 6.4 | Sect. B | ||||||

V=16 Type-R Hardness HRC55 |

86° | R77061 | 6.8 | L | ||||

| R77561 | 4.1 | M | ||||||

| R77762 | 1.6 | SS | ||||||

| R77861 | 3.0 | Sect. | ||||||

| RS7661 | 6.4 | Sect. B | ||||||

| 88° | R77081 | 6.8 | L | |||||

| R77581 | 4.1 | M | ||||||

| R77782 | 1.6 | SS | ||||||

| R77881 | 3.0 | Sect. | ||||||

| R7768S | 6.4 | Sect. B | ||||||

V=16 Type-T Hardness HRC55 |

86° | 19 | T77061 | 6.5 | L | |||

| T77561 | 4.0 | M | ||||||

| T77762 | 1.5 | SS | ||||||

| T77861 | 2.9 | Sect. | ||||||

| T7766S | 6.2 | Sect. B | ||||||

| 88° | T77081 | 6.5 | L | |||||

| T77581 | 4.0 | M | ||||||

| T77782 | 1.5 | SS | ||||||

| T77881 | 2.9 | Sect. | ||||||

| TS7681 | 6.2 | Sect. B | ||||||

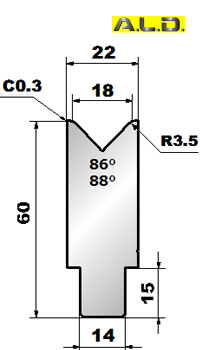

V=18 Hardness HRC55 |

86° | 18 | 22 | A78061 | 1000kN/m | 60 | 7.3 | L |

| A78561 | 4.4 | M | ||||||

| A78762 | 1.7 | SS | ||||||

| A78861 | 3.2 | Sect. | ||||||

| S78661 | 6.9 | Sect. B | ||||||

| 88° | A78081 | 7.3 | L | |||||

| A78581 | 4.4 | M | ||||||

| A78782 | 1.7 | SS | ||||||

| A78881 | 3.2 | Sect. | ||||||

| S78681 | 6.9 | Sect. B | ||||||

V=18 Type-R Hardness HRC55 |

86° | R78061 | 7.3 | L | ||||

| R78561 | 4.4 | M | ||||||

| R78762 | 1.7 | SS | ||||||

| R78861 | 3.2 | Sect. | ||||||

| RS8661 | 6.9 | Sect. B | ||||||

| 88° | R78081 | 7.3 | L | |||||

| R78581 | 4.4 | M | ||||||

| R78782 | 1.7 | SS | ||||||

| R78881 | 3.2 | Sect. | ||||||

| RS8681 | 6.9 | Sect. B | ||||||

V=18 Type-T Hardness HRC55 |

86° | 21 | T78061 | 7.0 | L | |||

| T78561 | 4.3 | M | ||||||

| T78762 | 1.7 | SS | ||||||

| T78861 | 3.1 | Sect. | ||||||

| TS8661 | 6.7 | Sect. B | ||||||

| 88° | T78081 | 7.0 | L | |||||

| T78581 | 4.3 | M | ||||||

| T78782 | 1.7 | SS | ||||||

| T78881 | 3.1 | Sect. | ||||||

| TS8681 | 6.7 | Sect. B | ||||||

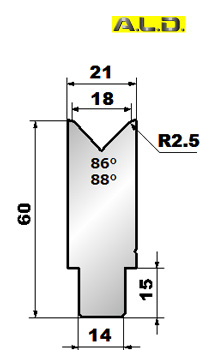

V=20 Hardness HRC55 |

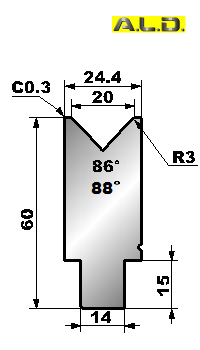

86° | 20 | 24.4 | A79061 | 1000kN/m | 60 | 7.8 | L |

| A79561 | 4.8 | M | ||||||

| A79762 | 1.9 | SS | ||||||

| A79861 | 3.5 | Sect. | ||||||

| S79661 | 7.5 | Sect. B | ||||||

| 88° | A79081 | 7.8 | L | |||||

| A79581 | 4.8 | M | ||||||

| A79782 | 1.9 | SS | ||||||

| A79881 | 3.5 | Sect. | ||||||

| S79681 | 7.5 | Sect. B | ||||||

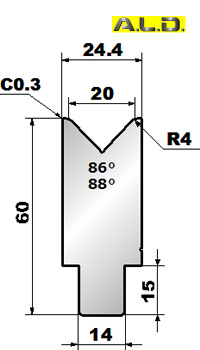

V=20 Type-R Hardness HRC55 |

86° | R79061 | 7.8 | L | ||||

| R79561 | 4.8 | M | ||||||

| R79762 | 1.9 | SS | ||||||

| R79861 | 3.5 | Sect. | ||||||

| RS9661 | 7.5 | Sect. B | ||||||

| 88° | R79081 | 7.8 | L | |||||

| R79581 | 4.8 | M | ||||||

| R79782 | 1.9 | SS | ||||||

| R79881 | 3.5 | Sect. | ||||||

| RS9681 | 7.5 | Sect. B | ||||||

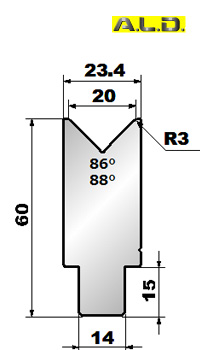

V=20 Type-T Hardness HRC55 |

86° | 23.4 | T79061 | 7.5 | L | |||

| T79561 | 4.6 | M | ||||||

| T79762 | 1.8 | SS | ||||||

| T79861 | 3.3 | Sect. | ||||||

| TS9661 | 7.2 | Sect. B | ||||||

| 88° | T79081 | 7.5 | L | |||||

| T79581 | 4.6 | M | ||||||

| T79782 | 1.8 | SS | ||||||

| T79881 | 3.3 | Sect. | ||||||

| TS9681 | 7.2 | Sect. B | ||||||

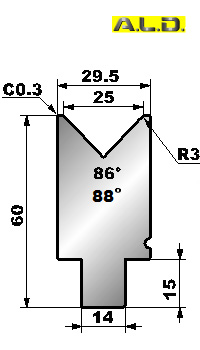

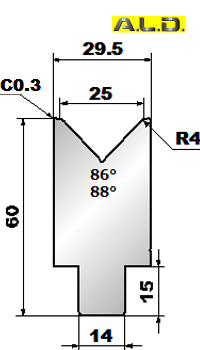

V=25 Hardness HRC55 |

86° | 25 | 29.5 | A82061 | 1000kN/m | 60 | 8.9 | L |

| A82561 | 5.5 | M | ||||||

| A82762 | 2.1 | SS | ||||||

| A82861 | 3.9 | Sect. | ||||||

| S82661 | 8.6 | Sect. B | ||||||

| 88° | A82081 | 8.9 | L | |||||

| A82581 | 5.5 | M | ||||||

| A82782 | 2.1 | SS | ||||||

| A82881 | 3.9 | Sect. | ||||||

| S82681 | 8.6 | Sect. B | ||||||

V=25 Type-R Hardness HRC55 |

86° | R82061 | 8.9 | L | ||||

| R82561 | 5.5 | M | ||||||

| R82762 | 2.1 | SS | ||||||

| R82861 | 3.9 | Sect. | ||||||

| RS2661 | 8.6 | Sect. B | ||||||

| 88° | R82081 | 8.9 | L | |||||

| R82581 | 5.5 | M | ||||||

| R82782 | 2.1 | SS | ||||||

| R82881 | 3.9 | Sect. | ||||||

| RS2681 | 8.6 | Sect. B | ||||||

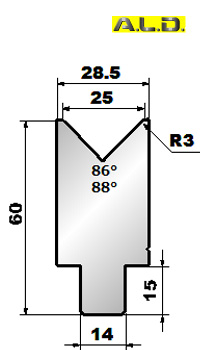

V=25 Type-T Hardness HRC55 |

86° | 28.5 | T82061 | 8.7 | L | |||

| T82561 | 5.3 | M | ||||||

| T82762 | 2.1 | SS | ||||||

| T82861 | 3.8 | Sect. | ||||||

| T8266S | 8.3 | Sect. B | ||||||

| 88° | T82081 | 8.7 | L | |||||

| T82581 | 5.3 | M | ||||||

| T82782 | 2.1 | SS | ||||||

| T82881 | 3.8 | Sect. | ||||||

| TS2681 | 8.3 | Sect. B |

- AFH die has special relief in order to gain the perfect alignment and tooling origin. Please be sure to use the same angle for combination to obtain the origin position. If the origin position is determined by different angle combination, the first bend for the product may be more acute than expected angle.

- Oxidized scale is peeled out from SPH( hot rolled steel ) when SPH material is bent, so clean the die groove regularly. AX Tool ( best for stainless and heavy gauge plate bending) is recommended for SPH material bending.