- Special Tools Guide

- R Beading

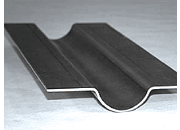

R Beading

SPCC : 0.6 - 2.3mm SUS : 0.6 - 2.0mm

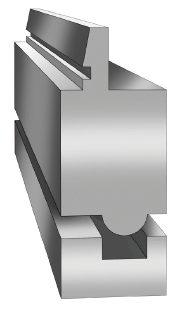

This tool creates half-shaped radius beading by one operation. Tool structure becomes quite simple at a lower cost. There is no material turn-over required.

| Work Sample | Work Profile | Tool Image |

|---|---|---|

|

|

|

Tool Spec.

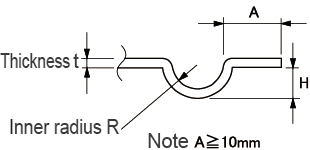

| Mat. | SPCC, SUS, AL |

| Thickness mm | 0.6 - 2.3 |

| Bead Hight (H) mm | (R+t) less |

| Inner Radius (R) mm | R(t x 3) - R10 |

Required Tonnage

Required bending tonnage /per m(SPCC)| Inner Radius (R) mm | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Thickness mm | 0.6 | 160 | 110 | 80 | 60 | 50 | 50 | 40 | 40 | 30 |

| 0.8 | - | 190 | 140 | 120 | 100 | 80 | 70 | 60 | 60 | |

| 1 | - | 300 | 230 | 180 | 150 | 130 | 110 | 100 | 90 | |

| 1.2 | - | - | 320 | 260 | 220 | 190 | 160 | 140 | 130 | |

| 1.6 | - | - | - | 460 | 380 | 330 | 290 | 260 | 230 | |

| 2 | - | - | - | - | 600 | 510 | 450 | 400 | 360 | |

| 2.3 | - | - | - | - | - | - | 600 | 530 | 480 | |

*Required Tonnage (kN/m) = {(90 x t2) / R} x 10

* Multiply x 1.5 to above figure for stainless steel, and x 0.6 to Al A5052.

Necessary Tonnage Calculation

| SPCC | Tonnage /m above x1.0 x product length(mm)÷1000 |

|---|---|

| SUS | Tonnage /m above x1.5 x product length(mm)÷1000 |

| AL | Tonnage /m above x0.6 x product length(mm)÷1000 |

Cautions

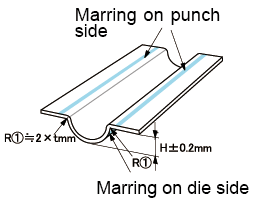

Marring

Marring appears on the punch hold-down area and die side surface.

Check Machine Capacity

Be sure that required tonnage gained by equation above does not exceed the machine capacity.

Product Accuracy

Product H dimension accuracy ± 0.2mm R1 on right side drawing becomes 2x thickness t.