- Special Tools Guide

- L-Bending Horizontal Type

L-Bending Horizontal Type

SPCC : 0.5 - 1.2mm SUS : 0.5 - 1.0mm

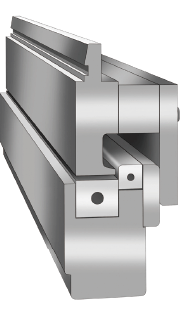

L-bend on edge tooling keeps work horizontal. When sectionalized punch with Ear or hinged punch is used, 4(four) sides bend-up box bending can be produced.

| Work Sample | Work Profile | Tool Image |

|---|---|---|

|

|

|

Tool Spec.

| Mat. | SPCC, SUS, AL |

| Thickness mm | 0.5 - 1.2(SUS less than 1.0) |

| Hight (A1) mm | 5-30 |

| Hight (A2) mm | 10-30 |

| Return (B) mm | 5-10 |

| Solid Length mm | L: 1000 , S: 500 (both punch and die) |

| Sect. Punch mm | 15,20,25,30,50,100(right ear),100(left ear),200 Total540 |

| Hinged Punch mm | 1 set left and right: 100(right ear),100(left ear) Total200 |

Required Tonnage

Required bending tonnage /per m(SPCC) unit kN/m| Thickness mm | 0.5 | 0.6 | 0.8 | 1 | 1.2 |

|---|---|---|---|---|---|

| Required Ton kN/m | 73 | 100 | 123 | 152 | 179 |

* Multiply x 1.5 to above figure for stainless steel, and x 0.6 to Al A5052.

Necessary Tonnage Calculation

| SPCC | Tonnage /m above x1.0 x product length(mm)÷1000 |

|---|---|

| SUS | Tonnage /m above x1.5 x product length(mm)÷1000 |

| AL | Tonnage /m above x0.6 x product length(mm)÷1000 |

Cautions

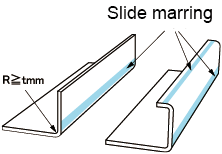

Marring

Marring appears as shown below. Polycarbonate shoulder piece reduces marring

Check Machine Capacity

Be sure that required tonnage gained by equation above does not exceed the machine capacity.

Thickness adjustment

Shoulder piece position must be adjusted by shims for each thickness.

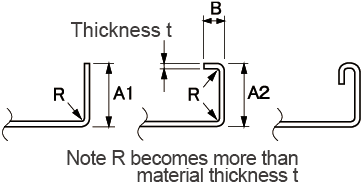

Product Accuracy

Inner R becomes more than thickness t .

Backgauge Plate Width

Back-side thrust plate has gap of with 60mm for back-gauge plate guidance. Please specify the back-gauge plate width for more than 60mm when ordering.