- Special Tools Guide

- Hard-Chromium(Cr.) Plating

Hard-Chromium(Cr.) Plating

Chromium plating is applied to die upper-surface /V groove This plating increases abrasion resistance property, rust-prevention and hardness. Also this plating minimizes Zinc-film adhesion on the die and performs mark-free effect by the combination with shoulder radius.

Plating

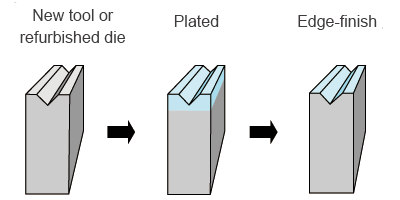

Plating Process

Feature and Caution

• Applicable to max. 4,000mm long 1V and 2V die• Stable plating and edge-finishing

• Sectionalized tool by cutting after plating

Cut charge will be added on plating charge

(Example)

L-size plating charge + 7 cuts charge

Applied Die

| Tool type | Tool No. | |

|---|---|---|

| 1V Die | 1V Die | 320 - 326 |

| Sash 1V Die | 070 - 076 | |

| 1V Die(V=32 - V160) | 13, 14, 18, 35 - 38, 39 | |

| Acute 1V Die | 340 - 342, 343 | |

| 2V Die | 121 - 127, 311, 314, 337 | |

| 3U Die | 12 | |

| R-Bend Die | 350 | |