- Special Tools Guide

- Modification

Modification

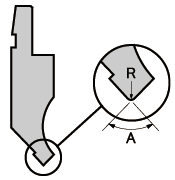

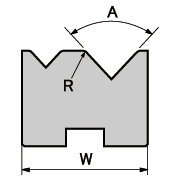

The modification such as bending angle, edge radius, die V-width can be made to standard tool. 45°/120° angle bend, which used to be made by minor adjustment of air-bend or use of urethane, now can be achieved accurately by bottoming of modified tool.

Additional modification such as tapered-groove work on standard tool or “EAR” shape can be made.

Standard Punch |

Standard Die |

||||||

| Standard Punch No. | Maximum R | Minimum A | Standard Die No. | Maximum R | Maximum W | Minimum A | |

|---|---|---|---|---|---|---|---|

| 3 | R8 | 30° | 13 | - | |||

| 4 | R5 | 60° | 14 | - | |||

| 8 | R3 | 30° | 18 | - | |||

| 16 | R5 | 60° | 35 | - | |||

| 17 | - | - | 36 | - | |||

| 20 | - | - | 37 | - | |||

| 45 | R5 | 70° | 38 | - | |||

| 50 | R5 | 70° | 39 | - | |||

| 150 | R5 | 70° | 104 | One-side | - | ||

| 46 | R5 | 70° | 1046 | One-side | - | ||

| 51 | R5 | 70° | 121 | R2 | 1 | 80° | |

| 47 | R5 | 70° | 123 | R2 | 1 | 80° | |

| 52 | R5 | 70° | 124 | R2 | 1 | 80° | |

| 48 | R5 | 70° | 125 | R2 | 1 | 80° | |

| 53 | R5 | 70° | 126 | R2 | 1 | 80° | |

| 49 | R3 | 30° | 127 | R2 | 1 | 80° | |

| 103 | R3 | 30° | 311 | 80° | |||

| 108 | R3 | 30° | 314 | 80° | |||

| 109 | R3 | 30° | 320 | 80° | |||

| 116 | R3 | 70° | 321 | 80° | |||

| 147 | R5 | 60° | 322 | 80° | |||

| 148 | R5 | 60° | 323 | 80° | |||

| 200 | R5 | 70° | 30210 | R2 | 1 | 80° | |

| 201 | R5 | 70° | 30240 | R2 | 1 | 80° | |

| 202 | R5 | - | 30310 | R2 | 1 | 80° | |

| 202801 | R5 | - | 30340 | R2 | 1 | 80° | |

| 203 | R5 | - | 30440 | R2 | 1 | 80° | |

| 203801 | R5 | - | 30540 | R2 | 1 | 80° | |

| 210 | R3 | 30° | 03640 | R2 | 1 | 80° | |

| 215 | R3 | 30° | 324 | 80° | |||

| 230 | 325 | 80° | |||||

| 231 | 326 | 80° | |||||

| 452 | R5 | 70° | 337 | 30° | |||

| 453 | R3 | 70° | 340 | ||||

| 155 | R3 | 70° | 341 | ||||

| 462 | R5 | 70° | 342 | ||||

| 151 | R5 | 70° | 343 | ||||

| 463 | R3 | 70° | 7001 - 7601 | ||||

| 156 | R3 | 70° | 70801 - 76801 | ||||

* Be sure to confirm the machine capacity and allowable tool tonnage before bending.

* No modification is applied for R-change, W-change Angle A-change by the combinations.

* Contact Amada for area in Blue above.

* Area in gray is discontinued.