- Special Tools Guide

- R-Bend Counter Type

R-Bend Counter Type

SPCC : 0.6 - 2.3mm SUS : 0.6 - 2.0mm

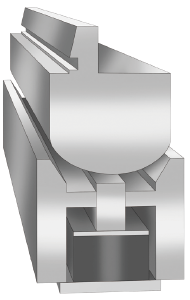

This application is suitable for larger R bending. The counter part in the die bottom controls rapid bending and work for prevention of multiple-breakage. Also this tool has versatility because only punch is replaced for required radius.

| Work Sample | Work Profile | Tool Image |

|---|---|---|

|

|

|

Tool Spec.

| Mat. | SPCC, SUS, AL |

|---|---|

| Thickness mm | 0.6 - 2.3 |

| Angle | 70° more |

| Outer radius mm | R5 - R50 |

Required Tonnage

unit kN/m| Thickness mm | 0.6 | 0.8 | 1 | 1.2 | 1.6 | 2 | 2.3 |

|---|---|---|---|---|---|---|---|

| Required Ton kN/m | 20 | 30 | 50 | 70 | 130 | 200 | 270 |

Necessary Tonnage Calculation

| SPCC | Tonnage /m above x1.0 x product length(mm)÷1000 |

|---|---|

| SUS | Tonnage /m above x1.5 x product length(mm)÷1000 |

| AL | Tonnage /m above x0.6 x product length(mm)÷1000 |

Cautions

Marring

Marring appears if the work is not covered by protective sheet. Therefore the marring countermeasure has to be taken by such as urethane sheet and mark-free tape.

Side Marring

Side Marring

Check Machine Capacity

Be sure that required tonnage gained by equation above does not exceed the machine capacity.

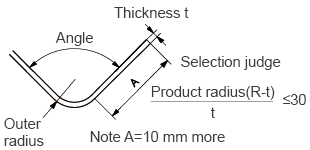

Selection judgment

Guide line : If product inner radius ÷ thickness t becomes bigger than 30, Counter-Type can be recommended.

Example) Product inner radius 30mm and thickness t 1.2mm

30÷1.2 = 25

Therefore Air-bend type or General type is recommended.

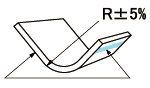

Product Accuracy

Accuracy of product R dimension R± 5%. Example: Product R=30 mm. 30x0.05 =1.5 Therefore R30±1.5mm.