- Special Tools Guide

- R-Bend General Type

R-Bend General Type

SPCC : 0.6 - 2.3mm SUS : 0.6 - 2.0mm

This application can gain stable accuracy because the punch presses the work into the die bottom. And R-Bend can be performed even if radius area has notching or holes internally. But this tool has no versatility because each tool is dedicated to required product radius and material thickness.

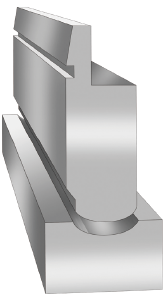

| Work Sample | Work Profile | Tool Image |

|---|---|---|

|

|

|

Tool Spec.

| Mat. | SPCC, SUS, AL |

|---|---|

| Thickness mm | 0.6 - 2.3 |

| Angle | 70° more |

| Outer radius mm | R5 - R50 |

Required Tonnage

unit kN/m| Thickness mm | 0.6 | 0.8 | 1 | 1.2 | 1.6 | 2 | 2.3 |

|---|---|---|---|---|---|---|---|

| Required Ton kN/m | 50 | 90 | 150 | 210 | 370 | 580 | 760 |

Necessary Tonnage Calculation

| SPCC | Tonnage /m above x1.0 x product length(mm)÷1000 |

|---|---|

| SUS | Tonnage /m above x1.5 x product length(mm)÷1000 |

| AL | Tonnage /m above x0.6 x product length(mm)÷1000 |

Marring

Marring appears if the work is not covered by protective sheet. Therefore the marring countermeasure has to be taken by such as urethane sheet and mark-free tape.

Side Marring

Side Marring

Check Machine Capacity

Be sure that required tonnage gained by equation above does not exceed the machine capacity.

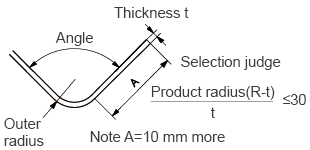

Selection judgment

Guide line : Product inner radius ÷ thickness t ≤30 by general type

Example) Product inner radius 35mm thickness t 1.2mm

35÷1.2 = 29.16

No multi-breakage occurs because factor is less than 30.

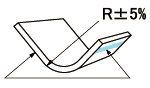

Product Accuracy

Accuracy of product R dimension R± 5%

Example: Product R=30 mm

30x0.05 =1.5 Therefore R30±1.5mm