- Special Tools Guide

- U-Bending (Counter-Holder Type)

U-Bending (Counter-Holder Type)

SPCC : 0.6 - 2.3mm SUS : 0.6 - 1.5mm

This tool bends two sides simultaneously and it results in small width. There is height limitation for two sides and two sides becomes wider in open end, but flatness and dimensional accuracy are quite good for mass production type.

| Work Sample | Work Profile | Tool Image |

|---|---|---|

|

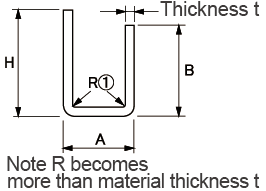

|

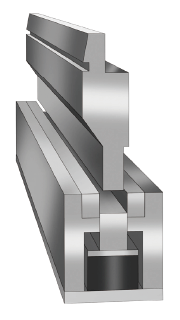

|

Tool Spec.

| Mat. | SPCC, SUS, AL |

| Thickness mm | 0.6 - 2.3(SUS less than 1.5) |

| Hight (A/B) mm | t x 4 - 30 |

| Width(C) mm | t x 4 - 30 |

Required Tonnage

Required bending tonnage /per m(SPCC) unit kN/m| Width(C) mm | 5 | 10 | 15 | 20 | 30 | |

|---|---|---|---|---|---|---|

| Thickness mm | 0.6 | 190 | 170 | 170 | 170 | 170 |

| 0.8 | 270 | 250 | 240 | 230 | 230 | |

| 1 | 350 | 310 | 300 | 290 | 280 | |

| 1.2 | 420 | 380 | 360 | 350 | 340 | |

| 1.6 | 600 | 530 | 500 | 480 | 470 | |

| 2 | 770 | 700 | 650 | 620 | 600 | |

| 2.3 | 920 | 800 | 760 | 740 | 720 | |

* Multiply x 1.5 to above figure for stainless steel, and x 0.6 to Al A5052.

Necessary Tonnage Calculation

| SPCC | Tonnage /m above x1.0 x product length(mm)÷1000 |

|---|---|

| SUS | Tonnage /m above x1.5 x product length(mm)÷1000 |

| AL | Tonnage /m above x0.6 x product length(mm)÷1000 |

Cautions

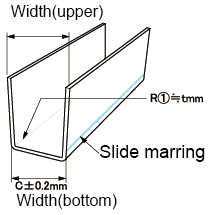

Marring

Marring appears on the die side.

Check Machine Capacity

Be sure that required tonnage gained by equation above does not exceed the machine capacity.

Product Accuracy

Product bottom width C accuracy ±0.2mm. Upper wide slightly wider than bottom wide. R1 becomes approx. material thickness.

Open Hight

The product is removed from the side way after bending by depending upon machine open height and product height H.